|

PPIę

Renishaw

Touch Probes

Touch trigger probes for your CMM

A comprehensive range of systems available to meet the

application needs and budget constraints of all users,

from simple feature checks on manually operated CMMs, to

complex form measurement on high-speed computer

controlled machines.

TP1 systems

The large, robust kinematic probe has a high degree of

overtravel. This attribute makes it ideal for use on

manual CMMs. The probe signal is carried to the CMM via

an external cable and the probe has adjustable stylus

force to help optimise its performance to the

application.

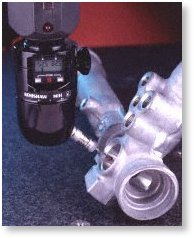

TP2 system

Ultra-compact standard kinematic probing system

The TP2 has become the industry-standard product, against

which all others are judged. It is a 13mm diameter standard

kinematic touch trigger probe with an M8 thread mount. It

has adjustable stylus force to enable the probe to support a

wide range of styli. The TP2 is small, light and compatible

with a wide range of accessories. It is suitable for both

manual and DCC machines.

TP20 systems

The TP20 is a 5-way, or 6-way, kinematic touch trigger probe

system. The two-piece design, comprising probe body and

detachable probe module(s), provides the facility to change

stylus configurations either manually or automatically

without the need for requalification of the stylus tips and

thereby gives significant time savings in inspection

routines.

A direct replacement for the industry standard Renishaw TP2

probe, the TP20 probe system brings a range of new benefits

to both manual and DCC CMM applications and can easily be

retrofitted to existing TP2 installations.

TP6

Robust probes for universal DCC and manual CMMs.

TP6 probes can carry longer styli than the smaller TP2/TP20

probes. The design is robust, with large overtravel and

adjustable trigger force. The TP6 has an M8 thread mount.

High

precision probes

A range of probes using strain-gauge and piezo mechanisms

for increased accuracy.

New generation strain gauge based probes, such as TP7 and

TP200, give users the benefits of higher system accuracy,

and should be considered for high tolerance workpieces, and

where the accessing of features requires long or complex

stylus arrangements.

New generation strain gauge based probes, such as TP7 and

TP200, give users the benefits of higher system accuracy,

and should be considered for high tolerance workpieces, and

where the accessing of features requires long or complex

stylus arrangements.

TP200 contact trigger

probe

High precision repeatability and 3D form measurement

with long styli is achieved by employing a novel type of

strain gauge structure to detect small displacements of

the stylus tip.

The TP200 probe incorporates micro strain gauge

transducers delivering excellent repeatability and

accurate 3D form measurement even with long styli. The

sensor technology gives sub-micron triggering

performance and eliminates the lobing characteristics

encountered with standard probes. The solid state ASIC

electronics within the probe ensure reliable operation

over millions of trigger points.

TP7M system

The TP7M uses strain gauge technology which provides higher

accuracy than standard touch trigger probes, The TP7M is a

multi-wired probe and must be used with the PH10M motorised

probe head or the PH6M fixed probe head. It is autojointed,

which provides the autochange function required on many DCC

CMMs.

|

|

|